Silicone 3D Printing Services

One of the most significant advancements in the field of 3D printing in recent years has been the development of a new technology that enables 3D printing using silicone as a viable option. This exciting development is projected to revolutionize additive manufacturing as it is known today. Additive manufacturing refers to building an object one layer at a time. Just as 3D printing has been a game changer in manufacturing by allowing us to produce tools, mechanical parts, and even functional prototypes in an entirely new way, silicone 3D printing is yet another innovative step forward for the manufacturing industry. 3D printing with silicone will serve many markets and truly impact the future of technology.

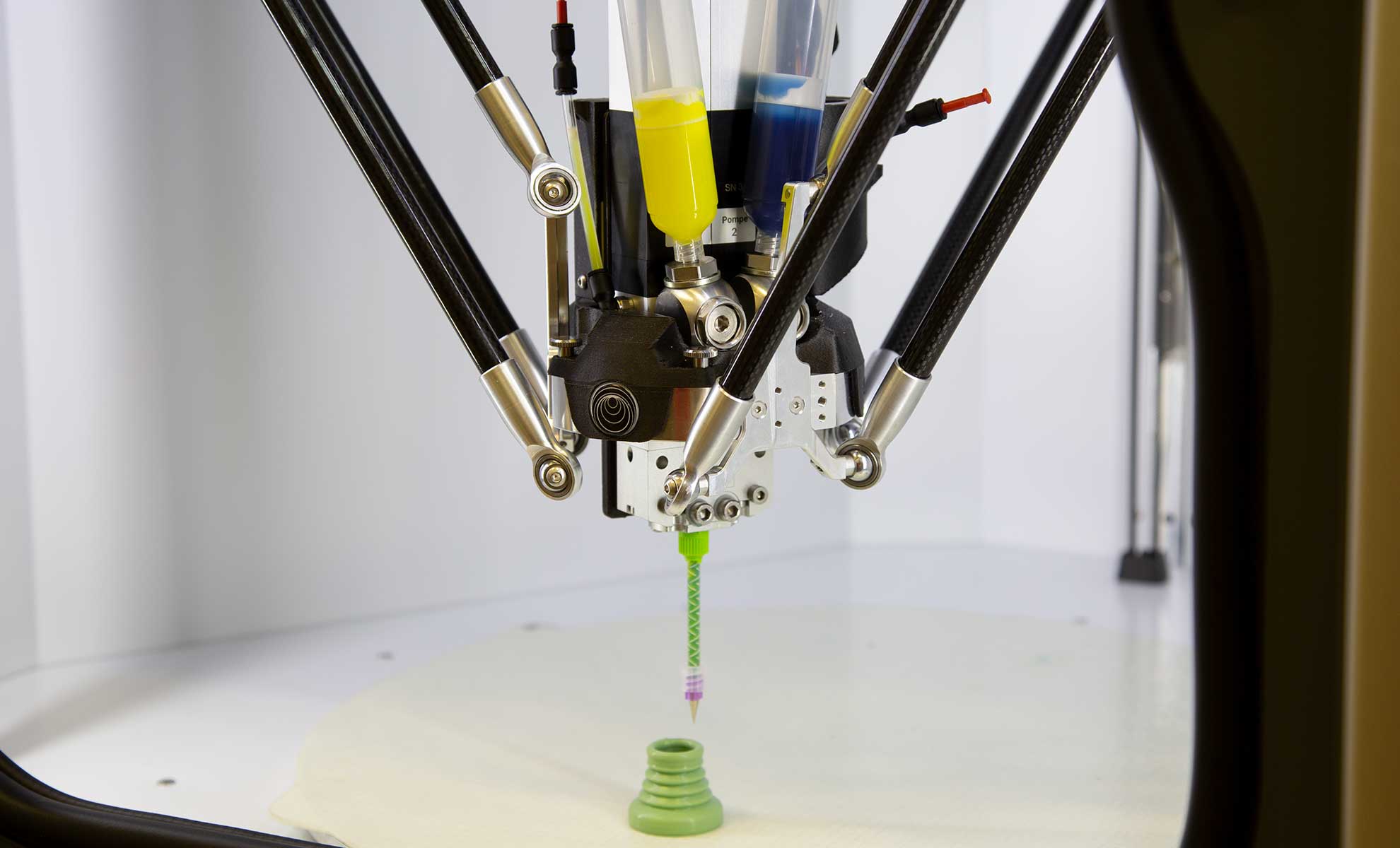

MatriMax is pleased to offer silicone 3D printing services and on-demand manufacturing of silicone products without molds, saving costs and time and with zero waste. MatriMix meets industrial standards with flawless efficiency in turnaround time, performance, and price. Utilizing cutting-edge technology that facilitates the processing of high durometer LSR (Liquid Silicones Rubber) at the highest precision, reliability, and speed. This allows for direct fabrication of silicone parts without the use of molds for industrial and medical end-use products consistent with injection molding.

MatriMix Silicone 3D Printing Services

Whether you need prototypes or production parts, MatriMix can produce them for you quickly and on demand. We are your one-stop shop for precise, custom silicone 3D printed parts at an affordable price. Send your STL file to get an online quote and lead time within minutes. We print everything from single prototypes to thousands of production-grade parts.

Silicone 3D Printing Services

Groundbreaking Silicone 3D Printing

Silicone is an elastomer, which is a material that exhibits rubber-like properties. An elastomer is a polymer with viscoelasticity (viscosity and elasticity). As a synthetic rubber, silicone has been highly anticipated for use as an additive manufacturing material for quite some time. Why such great demand for silicone 3D printing? Silicone has numerous appealing characteristics:

- It is water and steam resistant

- Exceptional thermal stability – up to 392°F (200°C) and as low as -112° F (-80°C), with higher and lower ranges using some formulations

- Biocompatibility

- UV Resistant

- Flame retardant

- Tear resistant

- Ideal compression set for forming tight seals

- Electrical insulating capabilities, including underwater

- Oxidation resistant

- Compression and shear resistant

- It is food safe

- It can be sterilized

- It is available in different durometers (the measure of hardness of a material), colors, and translucency options.